Why Modern Floors Demand Cleaner Solutions: The Hidden Costs of Concrete Dust

Anyone who’s seen a floor renovation up close knows that concrete grinding can get messy—really messy. Fine dust gets everywhere: up your nose, on every surface, and sometimes travelling through air ducts far beyond the project’s scope. According to industry studies, airborne dust from traditional grinding isn’t just an inconvenience, it can be a health hazard and a major clean-up expense. This is a problem especially in busy factories, warehouses, or retail spaces that can’t afford disruption. That’s where dustless concrete grinding steps in, turning a notorious nuisance into a cleaner, safer, and more efficient solution.

Dustless concrete grinding is much more than a technical improvement—it’s a revolution for commercial, industrial, and even residential spaces that demand high standards of cleanliness and air quality. As pressure grows to keep environments spotless while minimising operational downtime, finding smarter, safer ways to prepare and restore floors has never been more critical. With customer expectations and safety regulations only increasing, understanding dustless concrete grinding isn’t just helpful; it’s vital for anyone managing buildings, frequenting work sites, or simply wanting a fresher, safer renovation process. The next sections dive into why this technique matters and how it shapes both project results and daily operations.

Dustless Concrete Grinding Explained: Cleaner Floors, Healthier Air, and Happier Workspaces

When most people imagine smoothing out old concrete, they picture clouds of gritty dust billowing across the room—a real frustration for facility managers and business owners. Dustless concrete grinding flips that image on its head. By using specialised diamond grinders attached to high-powered vacuums, this method traps nearly all dust right at the source. Instead of dirty air and surfaces, you’re left with a clean space ready for coating, lining, or redesign. Because the grinding equipment collects dust instantly, air quality improves and post-job cleaning is minimal.

The benefits extend far beyond aesthetics. Dustless methods mean less interference with machinery, stock, or employee activities elsewhere in the building. For industries where downtime is costly or impossible, this is more than convenient—it’s essential. Workers and customers are also shielded from harmful airborne particles that could otherwise linger long after the job is done. The result? Faster project times, healthier spaces, and a professional finish that sets a new standard for commercial and industrial renovations.

Why Dustless Concrete Grinding Delivers Real-World Results and Business Advantages

As a leading expert in dustless diamond grinding, UK Painting Systems Ltd brings decades of experience from projects spanning manufacturing, automotive, warehousing, and more. Their emphasis on a totally dust-free process isn’t just about convenience—it’s about minimising disruption and upholding fiercely high standards for client spaces. By using techniques that capture dust immediately, dustless concrete grinding keeps other operations running smoothly. This is particularly important for busy warehouses and production floors where shutdowns can cost thousands each hour.

Removing mess and health risks is only part of the story. UK Painting Systems Ltd’s approach to dustless concrete grinding ensures every project begins with a surface that’s perfectly prepped for the next stage. Whether customers need tough resin coatings, anti-slip paint, or safety line markings, the dust-free surface means longer-lasting finishes and easier future maintenance. Clean floors don’t just look better—they work better, lasting through years of heavy use and staying safer for everyone.

Preparation Makes Perfect: The Secret to Long-Lasting Industrial Floors

One misconception about flawless industrial floors is that the magic happens during the final coating. But seasoned professionals insist that great outcomes are built on meticulous preparation, and dustless concrete grinding is the cornerstone of that process. Every business, from automotive to retail, benefits from a floor that’s clean, even, and free from residual dust. By grinding and removing surface contaminants without scattering debris, businesses can avoid problems like coating failures, uneven surfaces, or costly repairs later on.

The attention paid to preparation sets up every other service UK Painting Systems Ltd offers, from water-based epoxy coatings to complex safety walkway patterns. When the groundwork is sound—quite literally—clients can expect coatings that stick better, last longer, and resist chemicals, traffic, and frequent cleaning. It’s an upfront investment with returns that are visible for years.

Reducing Disruption, Increasing Safety: Floor Projects That Fit Your Schedule

One persistent challenge in industrial floor work is balancing upgrades against daily operations. Closing off work zones isn’t just distracting—sometimes it’s not possible at all. Dustless concrete grinding directly answers that concern. The system’s containment means other facility areas can carry on as normal, with minimal impact. Whether a client operates 24/7 or has unique workflow patterns, the approach can be scheduled and managed around their busiest times.

What’s more, strict adherence to Health & Safety Work Act standards—and worker training in COSHH PPE requirements—eliminates guesswork and reduces liability. This commitment isn’t just compliance for the sake of paperwork; it’s about building trust and making sure every project runs smoothly from first inspection to final handover. In today’s world, where employee safety and operational flexibility are top priorities, the dustless method is fast becoming an industry standard.

Cleaner Methods, Better Futures: Eco-Friendly and Technological Progress in Concrete Grinding

Environmental concerns are also pushing the construction and renovation industries to rethink legacy practices. Dustless concrete grinding marks a major step forward, keeping airborne particles out of both indoor and outdoor air streams. It also reduces the need for harsh chemical cleaners after grinding, meaning fewer irritants for building occupants and less risk for sensitive equipment nearby.

Looking ahead, more companies are integrating video documentation and modern marketing to show how their dustless process works—helping clients visualise the transformation and better understand maintenance options. This educational approach allows building managers, facility staff, and even visitors to appreciate the value of keeping spaces clean and safe.

UK Painting Systems Ltd’s Professional Commitment: Floors That Exceed Expectations

A reputation for flawless results doesn’t come by accident. For over 30 years, UK Painting Systems Ltd has made it their mission to deliver outstanding preparation and finish, blending traditional expertise with contemporary tools. Their philosophy is shaped by a client-first mindset—minimising disruption, keeping communication clear, and ensuring every surface is ready for years of demanding use.

Each project is approached with care: from initial inspection through to repairs, grinding, and high-performance coatings. The promise to deliver “excellent results with minimum disruption” is more than a slogan—it’s built into every step of their process, from customised technical advice to compliance with strict health standards. Clients count on them not just for clean, dust-free floors, but for durable assets that underpin a facility’s safety and productivity.

What Real Customers Say About Dustless Concrete Grinding Results

Choosing a new floor preparation method is easier when you hear from those who’ve already experienced the results. Many customers note the transformation that dustless concrete grinding achieves, not just in cleanliness but in the look and function of their floors. One particularly enthusiastic review stands out:

High quality professional work. Always completes in quoted timescales. The floors looked brand new after years of wear.

Feedback like this reflects both the immediate impact and long-term value that dustless concrete grinding brings to any project. Businesses and property managers who take the step towards cleaner, more efficient renovations find that great results aren’t just possible—they’re repeatable with the right expertise.

Cleaner Floors, Safer Buildings: Why Dustless Grinding Is a Smart Investment

In a world where operational efficiency and health are under the microscope, dustless concrete grinding stands out as a must-have upgrade. By combining advanced diamond grinding with powerful dust extraction, this process creates floors that are spotless, safe, and ready for anything. The expertise of UK Painting Systems Ltd ensures that every slab they touch is prepped perfectly for whatever comes next—be it heavy forklift traffic, strict hygiene codes, or eye-catching safety markings.

As more industries raise their standards and customers become better informed, dustless concrete grinding isn’t just an option—it’s the new expectation. With leaders like UK Painting Systems Ltd setting benchmarks in both technology and service, cleaner floors mean better futures for everyone involved.

Contact the Experts at UK Painting Systems Ltd

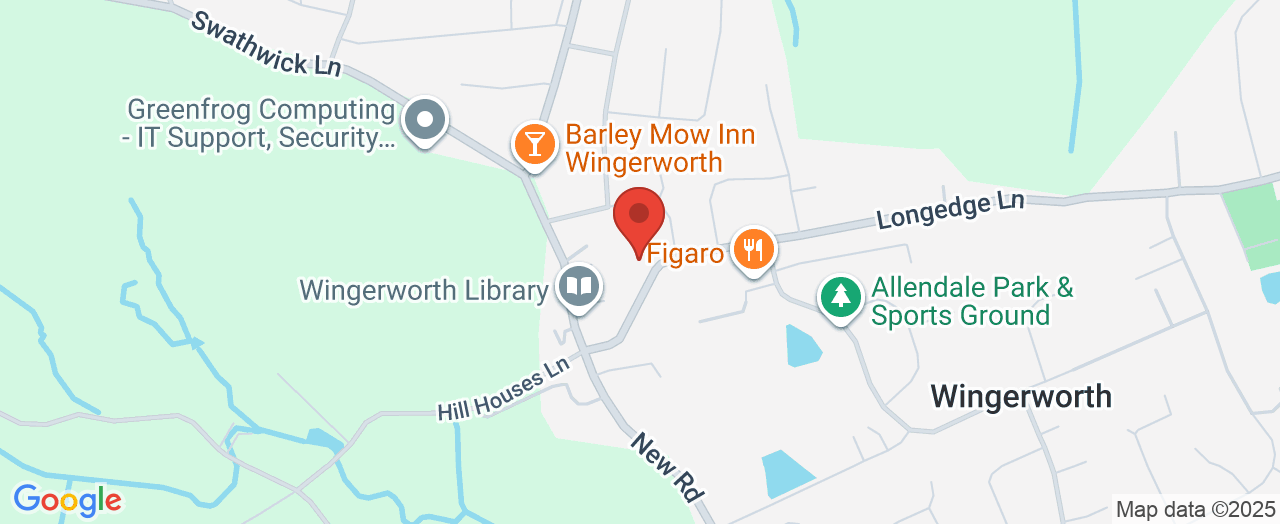

If you’d like to learn more about how dustless concrete grinding could benefit your floors or next building project, contact the team at UK Painting Systems Ltd.

📍 Address: 240 Longedge Ln, Wingerworth, Chesterfield S42 6PS, United Kingdom

📞 Phone: +44 7885 107944

🌐 Website: www.ukpaintingsystems.com

UK Painting Systems Ltd Location and Availability

Business Hours:

📅 Monday: 8:00 AM – 6:00 PM

📅 Tuesday: 8:00 AM – 6:00 PM

📅 Wednesday: 8:00 AM – 6:00 PM

📅 Thursday: 8:00 AM – 6:00 PM

📅 Friday: 8:00 AM – 6:00 PM

📅 Saturday: ❌ Closed

📅 Sunday: ❌ Closed

Add Row

Add Row  Add

Add

Write A Comment